How do we produce machine blown glass cups

Pulished on Mar. 03, 2023How do we produce machine blown glass cups

Machine blown glass craft is a manufacturing process that uses a machine to create glassware products such as cups, bowls, and vases. This process involves the use of molten glass, which is blown into molds by a machine to create the desired shape. Machine blown glass is a highly efficient and cost-effective method of creating glassware, which makes it popular in the industry. Garbo Glassware is one of the top factories of this craft for glassware products.

The raw material used for manufacturing glassware products is a mixture of various chemicals that are melted together to form molten glass. These chemicals include silica sand, soda ash, limestone, and other additives. Silica sand is the primary ingredient, and it is obtained from naturally occurring sources such as beaches, riverbeds, and deserts. Soda ash and limestone are added to reduce the melting point of the silica sand and to provide the glass with certain properties such as transparency and durability.

Silica sand is a naturally occurring compound made up of silicon and oxygen. It is a common mineral found in the earth's crust and is used in various industrial applications. Soda ash, on the other hand, is a chemical compound made up of sodium carbonate and is produced synthetically. Limestone is a sedimentary rock that is composed primarily of calcium carbonate and is also obtained from natural sources.

The raw material used in the manufacture of glassware is safe for human health when used as a material for our daily life glass drinking cup. The chemicals used in the manufacture of glassware are carefully selected to ensure that they do not pose any health risks. Silica sand, soda ash, and limestone are all natural compounds that are non-toxic and safe for human use.

To convert the solid raw material into liquid, the raw materials are first crushed into a fine powder and mixed together in precise proportions. The mixture is then heated in a furnace at extremely high temperatures, typically between 1500-2000 degrees Celsius. As the mixture heats up, it begins to melt and form a molten glass that is then ready for processing.

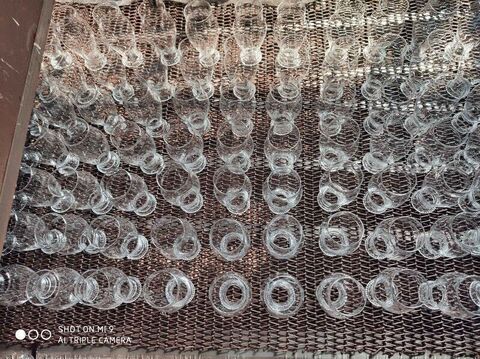

The liquid raw material is then processed in a glass cup mold using a process called blowing. In this process, the molten glass is placed into a mold that is shaped like the desired end product. The machine then uses compressed air to blow the molten glass into the shape of the mold. This process creates a brand new transparent glass cup from the high-temperature liquid. The process is highly precise, and the machine can create identical products every time.

The blown step works by using a machine that blows the molten glass into the desired shape. The machine has a nozzle that releases the molten glass into the mold, and compressed air is then used to blow the glass into the mold's shape. The process is carefully controlled to ensure that the glass is evenly distributed throughout the mold and that the final product is of high quality.

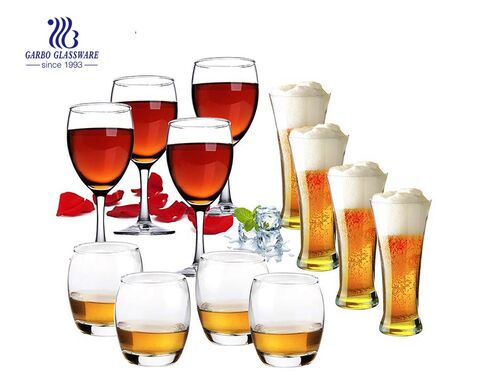

Machine blown glass cups have several features that differentiate them from other manufacturing crafts. These features include their precise shape and size, their uniform thickness, and their clarity. Machine blown glass cups are highly consistent in their shape and size, which makes them ideal for use in mass production. They are also highly durable and resistant to breakage, making them ideal for use in households and restaurants.

The advantages of a machine blown glass cup include their cost-effectiveness, their uniformity in shape and size, and their high durability. Machine blown glass cups are highly efficient to produce, which makes them an affordable option for manufacturers. They are also highly consistent in their shape and size, which makes them ideal for use in mass production. They are highly durable and resistant to breakage, making them an excellent choice for use in households and restaurants.

Generally speaking, machine blown glass craft is a highly efficient and cost-effective method of creating glassware products such as cups, bowls, and vases. The raw material used in the manufacture of glassware products is carefully selected to ensure that it is safe for human health when used as a material for daily use glass drinking cups. The raw material is converted to liquid by heating it in a furnace at high temperatures, and the liquid is then processed in a glass cup mold using a blowing process that uses compressed air to create the desired shape. Machine blown glass cups are highly consistent in their shape and size, making them ideal for mass production, and they are also highly durable and resistant to breakage, making them an excellent choice for use in households and restaurants.

Furthermore, the advantages of machine blown glass cups extend beyond their cost-effectiveness, uniformity, and durability. They are also highly versatile in terms of design and can be created in a variety of shapes and sizes to meet the demands of different consumers. Additionally, machine blown glass cups have a high level of transparency, which enhances the visual appeal of the product and allows consumers to appreciate the color and texture of the liquid inside the cup.

Machine blown glass cups also have a lower carbon footprint compared to other manufacturing crafts. The process of creating glassware products from raw materials requires a significant amount of energy, but the use of machines in the blowing process reduces the energy consumption and the carbon emissions associated with the manufacturing process. As a result, machine blown glass cups are an environmentally friendly choice for consumers who are conscious about their carbon footprint.

Moreover, machine blown glass cups have a longer lifespan than other types of cups. They are highly resistant to chipping and cracking, which reduces the need for frequent replacements. This results in lower costs for consumers and reduces the amount of waste generated from discarded cups. Additionally, machine blown glass cups can be recycled, which further reduces their environmental impact and enhances their sustainability.

In terms of safety, machine blown glass cups are designed to be safe for use in the food and beverage industry. They are made from non-toxic materials that do not leach harmful chemicals into the liquid inside the cup. This makes them ideal for use in households, restaurants, and other food service establishments.