Do you know how it's made wine glasses

Pulished on Dec. 11, 2021As a professional manufacturer, we are delighted to introduce the production process(Manual blown wine glass production process) of a red wine glass cup to you.

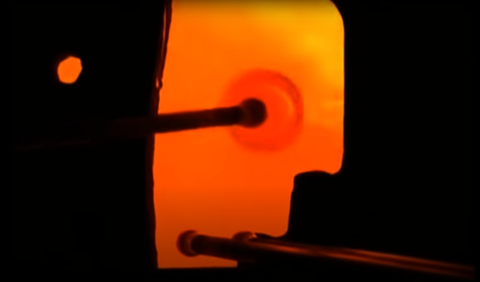

Production steps of Chinese red wine glass factory, first step:

Workers take a small amount of glass melt (the temperature of the glass melt is 1250°C-1450°C) from the glass furnace with a blowpipe.

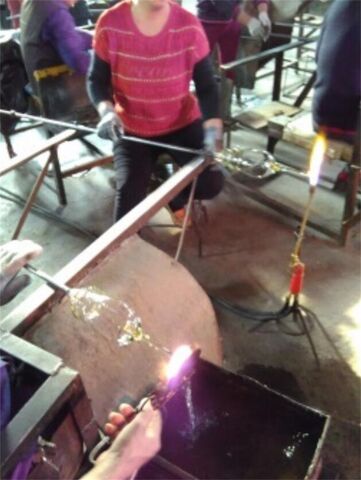

Production steps of Chinese red wine glass factory, second step:

Workers use the blowpipe to blow small bubbles. The small glass bubbles are the basis of the glass cup. The diameter of the small bubbles is usually 3~10 cm. The workers must check the small bubbles carefully during the blowing process. If the workers find that there are bubbles, streaks, impurities, etc. on the small bubbles, they must abandon it or it will cause defects in the glass. The shape of small bubbles should be blown round and the wall thickness to the small bubbles should be evenly, which directly determines the quality of the glass product.

Production steps of Chinese red wine glass factory third step:

Workers use a blow tube with small bubbles to take the glass melt from the glass melting furnace. This step is very important. The amount of material taken directly determines the weight of the product, the thickness of the bottom, and the thickness of the wall. At the same time, the method of taking the material also will determine the quality of the glass material. A good technique can avoid taking out the material liquid with bubbles, streaks, and impurities, and it can also avoid the formation of new bubbles during the reclaiming process.

Production steps of Chinese red wine glass factory fifth step:

After the material is taken out, it is shaped in a shaping mold. After shaping a similar shape according to the product shape, the shaped blank is placed in the mold and blown. Blowing is the most critical link in the glass forming process.

Production steps of Chinese red wine glass factory sixth step:

The level of blowing technology directly determines the brightness of the glass and the uniformity of the wall thickness. Generally, experienced veterans are engaged in this process. After the blowing in the mold is completed, the wine glasses without stiffening are directly fed into the annealing kiln for annealing, and the wine glasses with tall feet need to be stretched and bottomed before annealing.

Production steps of Chinese red wine glass factory seventh step: Annealing process.

The annealing process is the process of removing the internal stress of the glass. The product undergoes a process of high temperature and then cooling in the annealing kiln. During the annealing, the highest point temperature reaches about 540°C. This process usually takes 120-180 minutes and runs for 30 meters in the annealing kiln.

Production steps of Chinese red wine glass factory eighth step: Cold working process

After the annealing is completed, it enters the cold working stage, which is the mouth process for a wine glass cup. At this process, cut, ground, and dry mouth treatments are carried out separately and the products with thick mouths must be polished well. The mouth of the glass becomes smooth and has the conditions for use after that. During the glass-making process, the workers in every step always meticulously grasped the utensils in their hands. In the strict production process, some products that cannot meet the standards will be eliminated.

Production steps of Chinese red wine glass factory ninth step: Post-processing

The main processes for post-processing include engraving, sandblasting, decals, gold -painting, color spraying.

Production steps of Chinese red wine glass factory tenth step: Quality control process

All products must undergo visual inspection and hand inspection by QC one by one before they can be packaged. Common defects of glass cups mainly include bubbles, streaks, impurities, scratches, uneven mouth, uneven bottom, and non-conforming size.